A Note About Images: The images used in our articles are for illustration purposes only and may not exactly match the content. They are meant to engage readers, but the text should be relied upon for accurate information.

Milling is a crucial process in the manufacturing and production of various products, spanning across industries like food, pharmaceuticals, construction, and electronics. If you’re someone involved in these fields or simply curious about manufacturing, understanding milling is key. In this article, we will delve into seven intriguing facts about milling, shedding light on its significance and the technologies driving this essential process. Get ready to embark on a journey to uncover the fascinating facets of this fundamental industrial process.

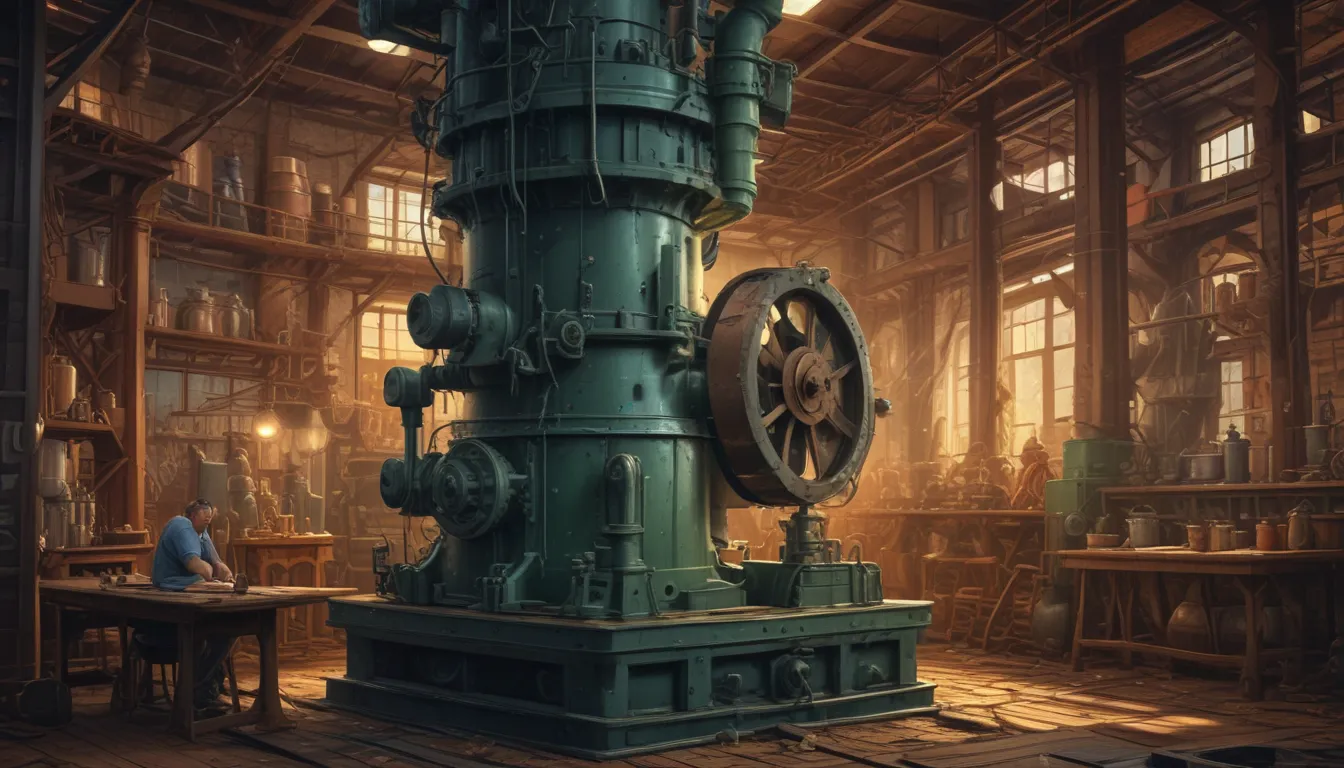

Milling: A Versatile Machining Process

Milling is a versatile machining process that uses rotary cutters to remove material from a workpiece. It is widely used in industries like automotive, aerospace, and manufacturing. The milling machine can perform a range of operations, from simple cutting and drilling to complex tasks like contouring and 3D surface machining.

Types of Milling Machines

Milling machines come in various types, each designed for specific applications. Some common types include vertical milling machines, horizontal milling machines, and CNC milling machines. These machines offer unique capabilities and advantages, catering to diverse machining requirements.

Achieving Precision and Accuracy with Milling

Milling excels in achieving precision and accuracy in the production of components. Advanced CNC technology and computer-aided design (CAD) software enable milling machines to create intricate and highly detailed parts with tight tolerances, meeting exact design specifications.

Versatility in Materials

Milling supports a wide range of materials, including metals, plastics, and composites. This versatility makes it a go-to choice for manufacturing components across different industries. Whether it’s aluminum, steel, or titanium, milling can effectively shape and manipulate various materials with ease.

Role in Prototyping and Production

Milling plays a vital role in prototyping and production processes, allowing for the creation of prototypes and mass production of parts with efficiency and consistency. From rapid prototyping to large-scale manufacturing, milling facilitates the seamless production of high-quality components for diverse applications.

Enhancing Efficiency and Productivity

Through advanced cutting tools and machining techniques, milling enhances efficiency and productivity in the manufacturing process. The ability to perform multiple operations in a single setup, along with high-speed machining capabilities, helps manufacturers optimize production workflows and meet demanding schedules.

Evolving with Technological Advancements

The field of milling continues to evolve with technological advancements, leading to the development of innovative techniques and equipment. From high-speed machining to 5-axis milling, the industry is consistently pushing boundaries, driving progress and innovation in machining.

Milling is a fundamental process that drives modern manufacturing, offering precision, versatility, and efficiency in producing a wide array of components. As technology advances, the capabilities of milling machines are set to expand further, shaping the future of manufacturing and engineering.

Conclusion

In conclusion, milling is a critical process with a significant impact on various industries. Understanding the fundamentals of milling provides valuable insights into material processing. By exploring the seven fascinating facts about milling, we gain a deeper appreciation for this essential practice and its influence on our daily lives. As technology progresses, milling will continue to evolve, fostering innovation and efficiency across sectors.

FAQs

- What are the different types of milling machines? Milling machines come in various types, including vertical, horizontal, and universal models, each designed for specific applications.

- How does milling differ from other machining processes? Milling involves removing material using rotary cutters, enabling the creation of complex shapes with high precision.

Explore the world of milling and its impact on our lives. Trust in our commitment to delivering quality and authentic content as you learn and discover with us.